Below you will find some examples of our past projects.

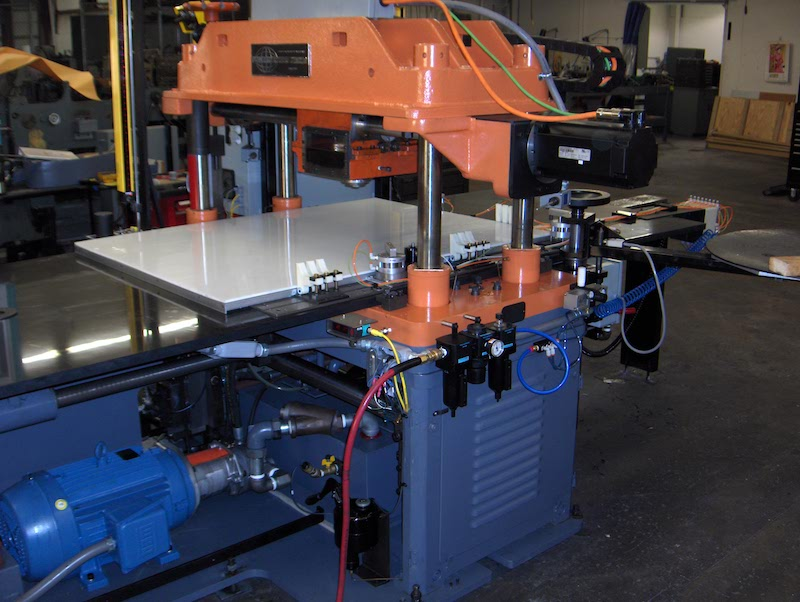

Hydraulic press upgrade

- Completely rebuilt mechanically

- Brand new control system and wiring

- 3-axis servo system and stand alone HMI

- Light curtain safety system

film feeding system upgrade

Completely redesigned feeding system. Now instead of changing sprockets customer simply enters the desired cut-off length on a screen. System is using 3 Allen Bradley servo drives.

cement plant, new construction

Maxtech was deeply involved in a design and construction of a brand new cement plant. Work performed on this project included: PLC and remote IO cabinets design, network design, instrumentation evaluation, field instrumentation interconnection diagrams, programming PLCs, setup and design of SCADA system and HMI screens, startup and commissioning, writing operating descriptions and other activities. This project took over two years to be completed. Unfortunately end customer is restricting publishing pictures from this project but more information is available at their web site: http://mcinniscement.com

Other cement and lime plants

Maxtech Systems performed various tasks at cement and lime plants throughout USA and Canada. Projects ranged from troubleshooting field instrumentation and writing operating descriptions for equipment to performing FAT tests, plant start up activities and technical support.